Multi-Bath

FVH series are our best-selling cleaning system chosen by many global companies due to its high reliability in cleaning performance. Achieves high dryness and solvent recovery, low solvent consumption and significantly reduced running costs.

Washable

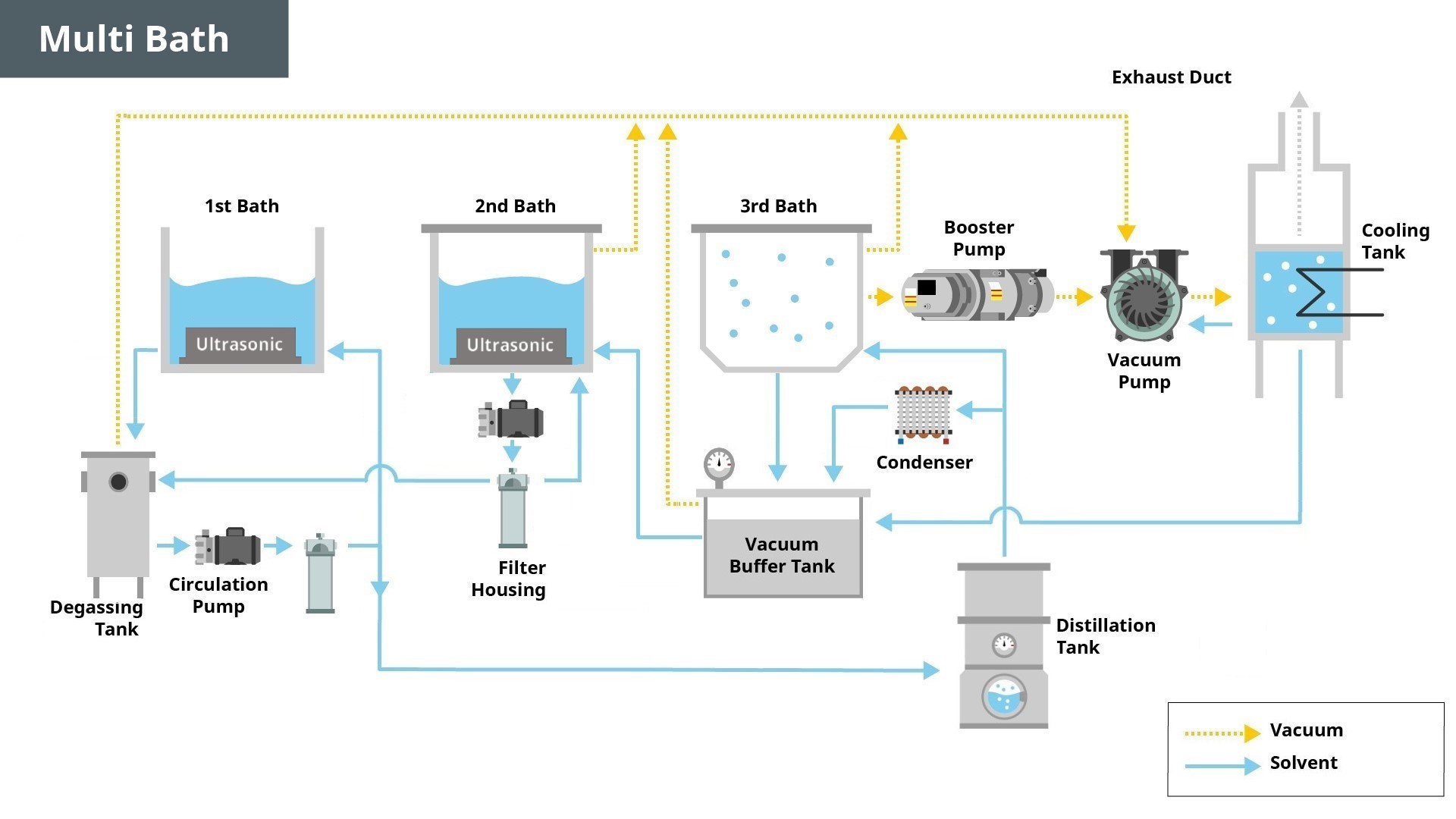

- 1st bath: degassing ultrasonic cleaning

- 2nd bath: vacuum ultrasonic cleaning

- 3rd bath: vapor cleaning and vacuum drying

- Uniform precision ultrasonic cleaning throughout the cleaning bath by adopting spherical wave type ultrasonics

- Vacuum ultrasonic cleaning of the second bath enables cleaning of blind holes and pressed parts

Dryness/Running Cost

- unique vacuum system achieves high dryness and solvent recovery

- Low solvent consumption and significant reduction in running costs

- Vacuum pumps are maintenance-free, less faulty and more reliable than dry pumps

- Heat medium oil life is reduced by 6,000 hours (= 3 to 4 times that of other companies) Heat medium oil cost, replacement frequency and downtime reduced by 1/3 to 1/4

Safety

- The liquid temperature of the first and second bath is managed at a fire range point of -10°C or less.

- The third bath’s vapor cleaning and vacuum drying in under vacuum conditions.

- Pumps and motors is equipped with safety explosion-proof specifications and carbon dioxide fire extinguisher as standard equipment.

Others

- The size of baths, the number of baths, the distillation capacity, etc. can be changed according to the required quality level.

- The third bath’s vapor cleaning and vacuum drying in under vacuum conditions.

- Pumps and motors is equipped with safety explosion-proof specifications and carbon dioxide fire extinguisher as standard equipment.

Why does ultrasonic cleaning work better when vacuumed (degassed)...?

It is said that the cleaning action of ultrasonic cleaning is generally caused by a powerful shock wave generated at the moment when cavitation (countless vacuum bubbles) is crushed, directly destroying dirt, dispersing it in liquid, and cleaning it.

Usually, a lot of air is dissolved in the solvent under atmospheric pressure, so the efficiency of generating vacuum bubbles is poor.

The degassing system adopted in this unit is a method of pulling out the air in the solvent in a degassing tank vacuumed to 40 KPa at all times, and circulating the degassing solvent to each washing tank, so that a stable degassing ultrasonic effect can always be obtained.

Examples of use of hydrocarbon-based cleaning machines

Hydrocarbon-based cleaning machines provide high cleaning power for various types of industrial products. Here's an example:

Precision Equipment Parts

- Automobile parts

- Engine parts

- Bearing parts

- Shaft part parts

- Drive part

Automotive-related parts

- Automobile parts

- Engine parts

- Bearing parts

- Shaft part parts

- Drive part

Metal parts

- Gears

- Measuring parts

- Various metalworking parts

Mechanical parts

- Compressor parts

- Machine tool parts

- Valve

- Pump parts

Standard specifications

| Target workpiece (WxDxH) mm | 300x400x200 (H350 including torser) |

| Equipment dimensions (WxDxH) mm | 3500x1720x2340 |

| Equipment weight | 2500kg |

| Cleaning method | 1st tank: Degassing ultrasonication + liquid external shaking Second tank: Vacuum ultrasonics 3rd tank: Vacuum beper cleaning |

| ultrasonic waves | First tank: 25KHz 750W, Second tank: 25KHz 1,000W |

| Drying method | Vacuum drying (reachable vacuum degree 0.3KPa or less) |

| Takt Time | 5-6 minutes |

| vacuum pump | Liquid-sealed vacuum pump + mechanical booster pump |

| Solvent capacity | 390L |

| Loader Unloader | 3 baskets each |